COMBI-BLOC ADVANTAGES

Compact Design

Increased Profitability

Reduced Manpower

Superior Quality

Enhanced Efficiency

Energy Saving

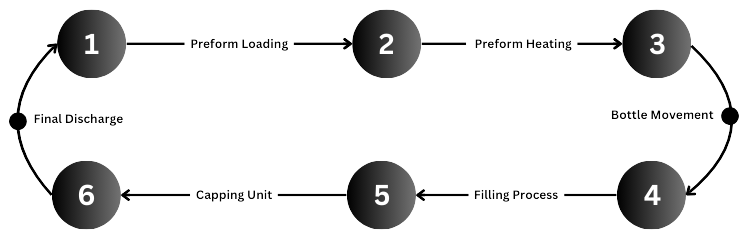

Combi-Bloc Operational Flow

- Blowing System

- Filling System

- Capping Unit

Technical Innovations

- Optimized cam curve for efficiency

- Reduced noise & improved stability

- Energy-saving, eco-friendly design

- Electrostatic dust removal & bottle neck protection

- Camera-based bottle neck inspection

- Enhanced preform handling & cap cleaning

- Servo motor stretching & mechanical mouth sealing

Mechanical Advancements

- High-speed, high-torque servo motor

- Electrohydraulic servo cylinder integration

- Stretch rod for precision shaping

- High-pressure valve & bottle neck sealing

Water Combi-Bloc Machine Model | ||||

Model | Blower Cavities | Filling Valves | Capping Heads | Capacity (BPH 1.5L/1L/0.5L) |

GTM – 06-18-06 | 6 | 18 | 6 | 5500 / 8000 / 12000 |

GTM – 08-24-08 | 8 | 24 | 8 | 7000 / 10000 / 16000 |

GTM – 10-32-10 | 10 | 32 | 10 | 9000 / 13500 / 20000 |

GTM – 10-40-10 | 10 | 40 | 10 | 12000 / 18000 / 30000 |

GTM – 12-40-15 | 12 | 40 | 15 | 12000 / 15000 / 24000 |

GTM – 14-45-15 | 14 | 45 | 15 | 13000 / 20000 / 28000 |

GTM – 16-50-15 | 16 | 50 | 15 | 15000 / 21000 / 30000 |

GTM – 18-60-20 | 18 | 60 | 20 | 20000 / 24000 / 30000 |

- Water Bottle Filling Machine

- Carbonated Bottle Filling Machine

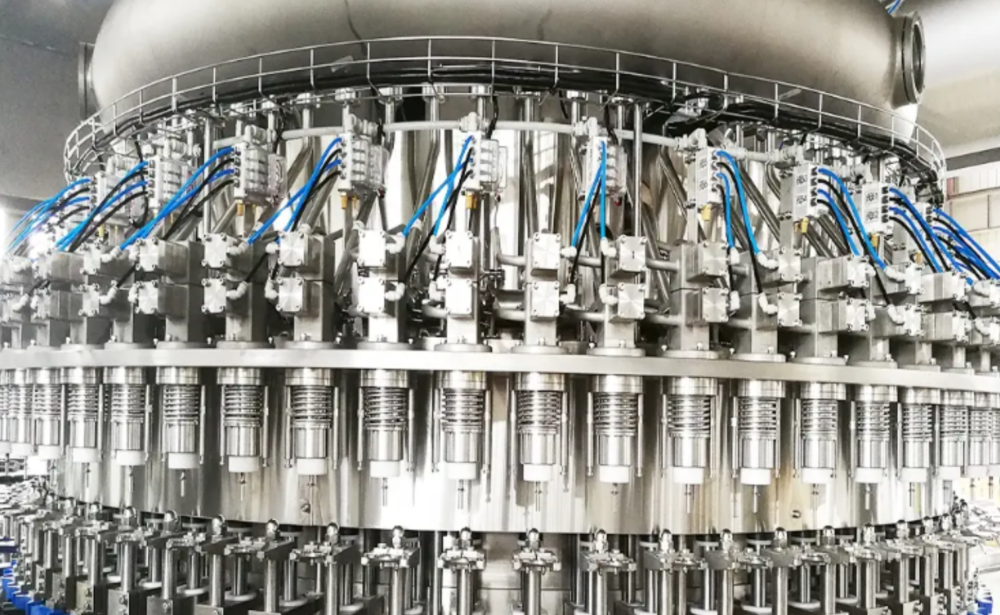

Advanced Water Bottle Filling Machine

Our water filling system is engineered for maximum efficiency and precision. The innovative flow meter technology ensures accurate filling, while adjustable settings allow seamless adaptation to various bottle sizes.

Key Features:

- Precision Flow Metering – Ensures accurate and efficient filling.

- Adjustable Volume – Easily adapts to different bottle sizes.

- Variable Speed – Supports fast and controlled filling.

- Contact-Free Operation – Low maintenance, no lift cylinder needed.

- Automated CIP – Ensures thorough post-production cleaning.

- No Bottle, No Fill – Prevents wastage, improves efficiency.

- Stainless Steel Build – Durable and hygienic structure.

Water Combi-Bloc Machine Model

Our range of Blowing-Filling-Capping machines offers different capacities to suit your production needs.

| Water Combi-Bloc Machine Model | ||||

Model | Blower Cavities | Filling Valves | Capping Heads | Capacity (BPH 1.5L/1L/0.5L) |

GTM – 06-18-06 | 6 | 18 | 6 | 5500 / 8000 / 12000 |

GTM – 08-24-08 | 8 | 24 | 8 | 7000 / 10000 / 16000 |

GTM – 10-32-10 | 10 | 32 | 10 | 9000 / 13500 / 20000 |

GTM – 10-40-10 | 10 | 40 | 10 | 12000 / 18000 / 30000 |

GTM – 12-40-15 | 12 | 40 | 15 | 12000 / 15000 / 24000 |

GTM – 14-45-15 | 14 | 45 | 15 | 13000 / 20000 / 28000 |

GTM – 16-50-15 | 16 | 50 | 15 | 15000 / 21000 / 30000 |

GTM – 18-60-20 | 18 | 60 | 20 | 20000 / 24000 / 30000 |

These high-performance systems provide superior efficiency, cost savings, and seamless operation, making them ideal for large-scale bottled water production.

Carbonated Beverage Combi-Bloc Machine Models | ||||

Model | Blower Cavities | Filling Valves | Capping Heads | Capacity (BPH 0.5L) |

GTM – 06-32-08 | 6 | 32 | 8 | 10,000 |

GTM – 08-40-10 | 8 | 40 | 10 | 15,000 |

GTM – 10-50-10 | 10 | 50 | 10 | 18,000 |

GTM – 12-60-12 | 12 | 60 | 12 | 21,000 |

GTM – 14-60-15 | 14 | 60 | 15 | 24,000 |

GTM – 16-80-15 | 16 | 80 | 15 | 27,000 |

GTM – 18-90-18 | 18 | 90 | 18 | 30,000 |

GTM – 20-108-20 | 20 | 108 | 20 | 36,000

|

With advanced automation, high-speed performance, and precise filling accuracy, our carbonated beverage filling machines provide an efficient and cost-effective solution for large-scale production.

Capper Technology

- Volumetric & mechanical filling valves

- Easy-to-clean tubular bowl design

- Automated CIP for maintenance

- Energy-efficient filling (12–15°C)

- 5–6× more precise volumetric valves

- Quick changeovers, no vent tubes

Capper Technology

- Volumetric & mechanical filling valves

- Easy-to-clean tubular bowl design

- Automated CIP for maintenance

- Energy-efficient filling (12–15°C)

- 5–6× more precise volumetric valves

- Quick changeovers, no vent tubes.